My First Aluminum Print

Yay!

After reading so much about Dan Berg’s experiments coating and printing metal on the Luminous Landscape Printing forums I figured I had to give it a try. After many back and forth messages with Dan I was ready to take the plunge.

The Metal

The metal is 0.025” 5025 aluminum from Metal Supermarkets. I had a painful time finding a local source as none of the roofing supply companies had any. Metal Supermarkets came to the rescue again (I used them for the galvanized metal that makes up my print viewing board). I had them cut me four 12×12” and four 12×18” pieces out of a 4×10′ sheet that was relatively clean of scratches.

The Cleaning

Oh man. The cleaning. I tried all sorts of ways to clean the metal to find what would be the fastest way.

- The dishwasher: This did NOT work. I tried one sheet of each size and while the bottom 3/4 of each sheet came out clean the top edges where they touched during washing was all discoloured. No amount of scrubbing would get rid of it.

- Metal polish: This kinda sorta worked. It really makes the aluminum go black until you buff it really hard. Not worth the effort

- Bon Ami and water: This cleaned reasonably well.

- Rubbing alcohol: This also cleaned reasonably well.

Next time around I will do the steps on the InkAid site: using dishwasher powder like Cascade and then following up with rubbing alcohol.

I also tried buffing the aluminum with 0000 steel wool. It certainly buffs but it also leaves obvious fine scratches. If you want a directional pattern to the underlying aluminum this is the way to do it. If you don’t… don’t use the steel wool!

The Coating

Dan uses InkAid to coat his metal. Unfortunately they don’t have any local sales channels. I’ve got an order in for a quart but didn’t want to wait for it to show up. David mentioned Daniel Smith sells Golden Digital Grounds so I picked up a bottle of that.

My first coating attempt was with my HVLP sprayer. Complete and total failure. It just sprayed globs everywhere. I’m sure it’s possible to do (the InkAid folks list it as one of the application methods) but I didn’t have the patience to play with pressure settings and whatnot. I fell back to using an $0.86 foam brush from Home Depot. It actually coated relatively easily. One coat in a horizontal direction, followed by a second in the vertical direction once the first coat dried. Total drying time was only about an hour per coat. Not bad!

The Printing

Once I got to this point it was honestly pretty easy. I ran the print on a Canon iPF5100 using POP Board as the media type. This kicks on front loading of the media and provides a perfectly flat printing path. I had to make sure to pull the printer far enough away from the wall so the sheet could come out the back during printing.

I made a custom profile for the aluminum sheet using my Spyder2. It read the target print surprisingly well.

The hardest part of printing is getting the aluminum to load straight. There’s one tiny orange mark you’re supposed to align the edge of the sheet with and it’s very easy to be slightly off and have the printer complain about the aluminum being crooked. When I did the profile target it took me six tries to get the sheet loaded properly. I had better luck this morning with the real print: it only took three tries.

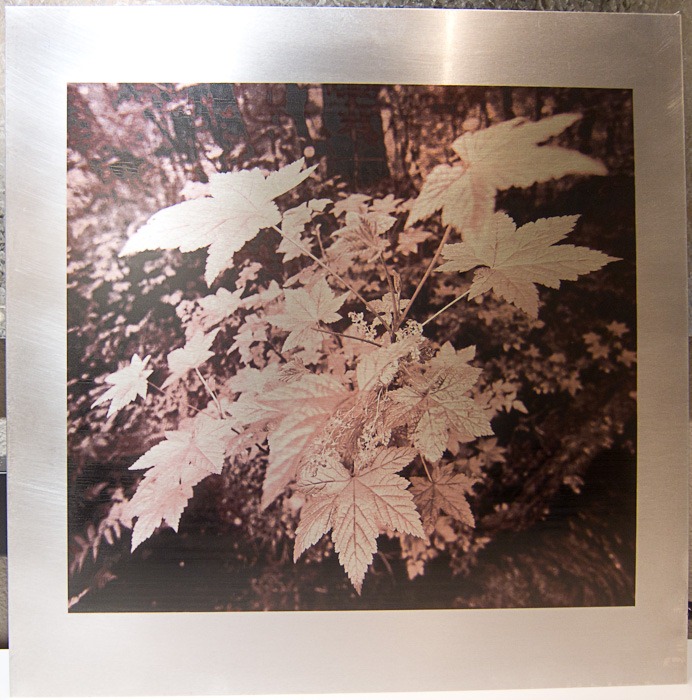

The Result

I’m quite pleased with the result considering I’ve never done this before. There are definitely some issues in the darkest areas of the print. The ink has cracked a bit on the coating and is rather splotchy in some of the very dark shadow areas. I’m not sure if there’s anything I can do about that since I can’t control the amount of ink the printer lays down. I wonder if the InkAid coating will work better.

The only thing I haven’t done at this point is apply a couple of coats of spray varnish to protect the print and add some more gloss. That’ll happen later today.

Leave a Reply